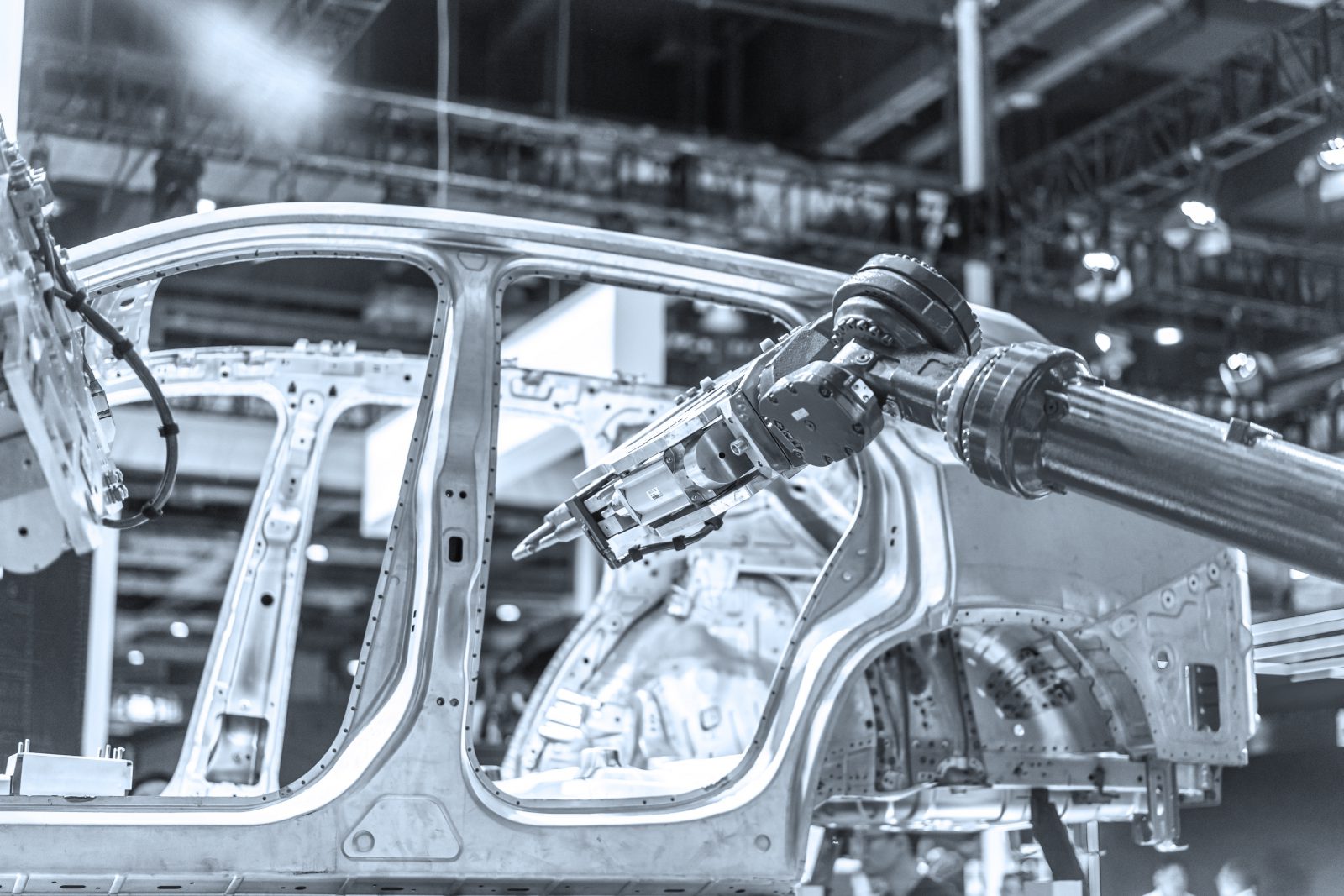

The Challenge – Robotic Assembly Line Design

Client: Electric vehicle manufacturer

Objective: Meet extremely compressed delivery schedule

An electric vehicle manufacturer with a new project to automate the assembly of an automotive seat challenged the chief engineer of an automation company. They were awarded the project weeks before Thanksgiving with a highly compressed delivery schedule. As a result, the client needed to engage a reliable partner to develop the design of a robotic work cell assembly system for manufacturing eight weeks after the project kick-off meeting. Ultimately a main layout, full assembly drawings, bill of materials, and detailed part drawings made up the deliverables package.

- The electric vehicle manufacturer was conducting concurrent product design while Sterling Engineering was designing the robotic work cell automation design.

- The project kick-off started weeks before Thanksgiving. The collaborative design spanned Thanksgiving/Christmas/New Year holidays, and deliverables needed to be released to manufacturing eight weeks after the project kick-off.

- Due to the new seat assembly / robotic automation technology, concurrent design was needed to accelerate the R&D effort to meet the tight deadlines.

Project Size

$128K

Duration

18 Weeks

Project Team

9 Engineers

Industry

Machinery Manufacturing

Robotic Line Assembly Solution

Our client specified their proprietary assembly line that would index the product. The workflow layout was verbally communicated, and Sterling Engineering’s team broke down each module and assigned it to the engineering teams. The automotive company specified which robot brand, and Sterling Engineering determined the model needed. After that, it would be up to Sterling Engineering to add details and dimensions to make this an efficient and precise layout.

Our work tasks were broken down into:

- Robot size specification

- Component delivery systems

- Machine locations

- Robot end effectors

- Work holding

Sterling Engineering assigned the lead design engineers and detail designers. The detail drawing work utilized an off-shift team to compress the schedule. The tasks were allocated to leverage all resources and allowed the teams to work concurrently around the clock.

The project was delivered on time and within the budget allowing the client to save the order. In addition, the Solidworks 3D-CAD models, detailed parts drawings, timing charts, and installation assembly drawings enabled them to secure revenue and keep their client.