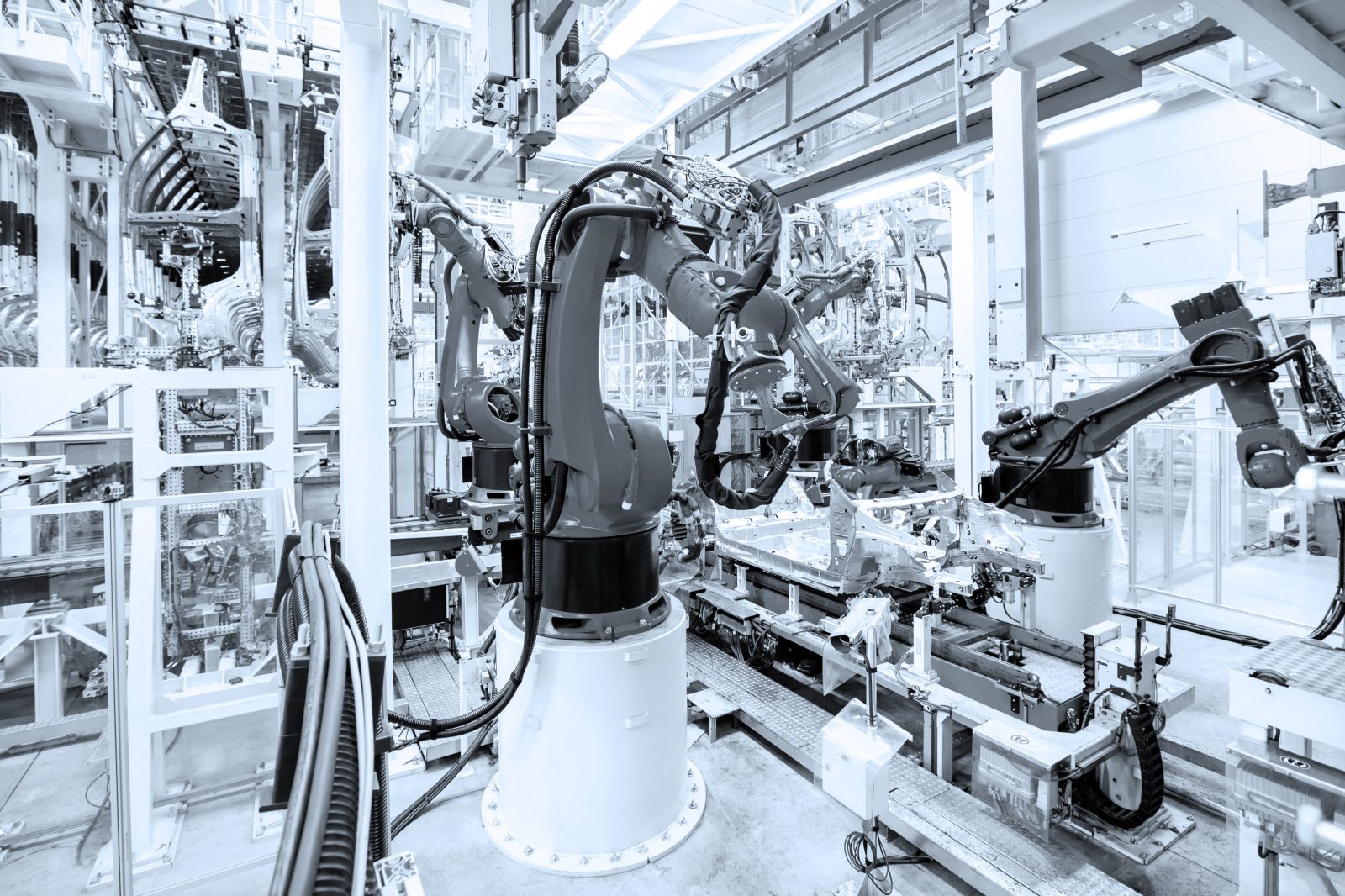

The Challenge – Robotic Work Cell

Client: Appliance Manufacturer

Objective: Design a robotic work cell

The owner of an automation company was challenged by a leading appliance manufacturer with a project to automate the assembly of a new oven design. In addition, the assembly process involved part picking, welding, verification/inspection, and assembly of the components onto the chassis of the next-generation residential oven. The client needed to engage a reliable partner to develop the design of a robotic work cell assembly system so that they could generate the revenue associated with the fabrication, assembly, controls, and installation of the production line.

- The client did not have the team expertise/capacity to deliver a project of this scale within the schedule needed by the end client.

- Project kick-off started after the New Year, and the complete engineering documentation set needed to be released to manufacturing within 16 weeks.

- Thirteen (13) robotic work cells, including vision systems, needed to be designed and detailed for fabrication.

Project Size

$490K

Duration

25 Weeks

Project Team

12 Engineers

Industry

Machinery Manufacturing

Robotic Work Cell Project Results

Our team included a Project Manager, a liaison between management teams, and Lead Project Engineers who coordinated the design/detailing effort over around-the-clock shifts to compress the delivery schedule.

At the kick-off meeting, Sterling Engineering worked with the client to sort through the sequence of operations needed to achieve the end client’s cycle time. During the meeting, the workflow layout was discussed to determine how to break down the system into modules with no-fly zones so that engineering design could begin. We worked with the client to specify the robots that could move the part masses through the kinematic motions needed to meet the production rate.

Because of the size of the design team required, our team focused on producing the main layout, full assembly drawings, bill of materials, detailed part drawings, and timing diagrams for release to manufacturing. This allowed the client to take on the project and generate the revenue associated with the production line’s fabrication, assembly, and installation.

The system was designed with Solidworks 3D-CAD assembly models, detailed part drawings, timing charts, and installation assembly drawings. These tools allowed Sterling Engineering to verify robotic tool interference resulting in a safe and efficient process layout. The automation line (13 Robotic / Vision work cell modules) was comprised of the following:

- Part feed

- Part/feature verification/inspection

- Spot and seam welding

- Vision inspection/quality

- Robot end effectors

- Work holding

- Robotic palletizing