The Challenge – Project Management

Client: Pharmaceutical Manufacturer

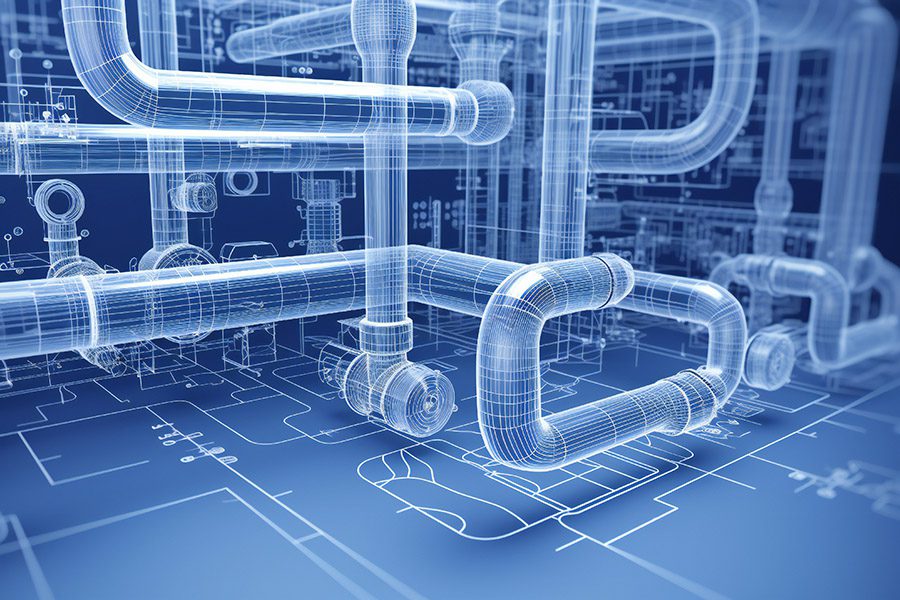

Objective: Overhaul their purified water utility rooms

A pharmaceutical manufacturing plant had safety and appearance concerns regarding their Purified Water piping and the layout of their water utility rooms. As their system was augmented over the years, additional piping was squeezed into the same constricted space. Ultimately, accessing the piping for any maintenance activity became costly, time-consuming, and nearly impossible. They did not have the resources to develop a conceptual and detailed design to address the issues.

Due to the required mechanical piping design, we actively sourced an MEP firm to subcontract/partner with us. They provided the majority of the design work for both phases, while the Sterling team provided project management.

Our Solutions

Phase 1 - Engineering Assessment & Conceptual Design

- Observed current state of piping and rooms. Identified needs/wants, categorized, and ranked them. Clarified scope using these rankings to prioritize solutions.

- Developed a conceptual design addressing the items in the scope.

- Generated cost estimates for conceptual design, and finalized scope based on cost and available funding.

Phase 2 - Detailed Design & RFP Process

- Finalized scope was used to develop detailed engineering design drawings and documentation.

- Design included architectural, structural, mechanical, piping, and fire protection.

- Detailed design package was provided to multiple general contractors to obtain bids for the construction work.

- Utilizing selection criteria and bid interviews, a general contractor was awarded the project.

The Results

Project Scope

Purified Water Tank Room

- Relocate large storage tanks

- Move 3 water softeners to Utility Room

- Replace piping

- Fix ceiling

- Remove fire sprinkler system connection

Purified Water Still Room

- Remove out-of-use still and plastic storage tanks

- Install new fire sprinkler connection

- Insulate top of 10,000 L PurW Tank

Utility Room

- Install 3 water softener tanks

- Create curbed area with drain

Project Duration

11 Months

Project Size

Phase 1: $31,000 Engineering

Phase 2: $75,000 Engineering

Project Team

Senior Engineering –

1 Project Manager, 1 Project Director

Utilized external partner for MEP and architectural